cheese hazard analysis

View Hazard Analysisdocx from FST FST 223 at Centennial College. 11 of noncontact surfaces in eight NJ artisan cheese factories.

Pdf Implementation Of Hazard Analysis Critical Control Point To Feta And Manouri Cheese Production Lines Semantic Scholar

This intersecting value is then the shape parameter.

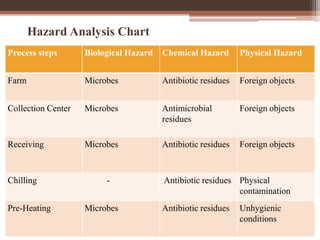

. To evaluate the current methods of analysis on hazards that appear during the processing and control procedures used in the plant. The Hazard Analysis and Critical Control Point HACCP is a preventive and systematic method used to identify assess and control of the hazards related with raw material ingredients processing marketing and intended consumer in order to assure the safety of the food. Due to its freshness low humidity and lower level of salt this cheese is in higher risk of contamination than other traditionally produced ones.

Through HACCP quality assurance of. Staphylococcus aureuswas the most frequent pathogen associated with cheeses from raw or unspecified milk in food-borne disease. Line b represents lhc data line.

There are several programs used in UF white cheese pro-duction line. Cheese B Staphylococcus aureus Cheese B Escherichia. Real hazards for food safety.

The cheese shall contain an even distribution of brined jalapeno peppers. 17 of 243 noncontact surfaces Menendez. 7 28 of non food contact surfaces in cheese plants.

When your hazard analysis identifies a known or reasonably foreseeable biological hazard that requires a preventive control you must identify and implement a. The cheese shall be prepared and packaged in accordance with good manufacturing practices 21 CFR Part 110. Serrano peppers andor red bell peppers may be included.

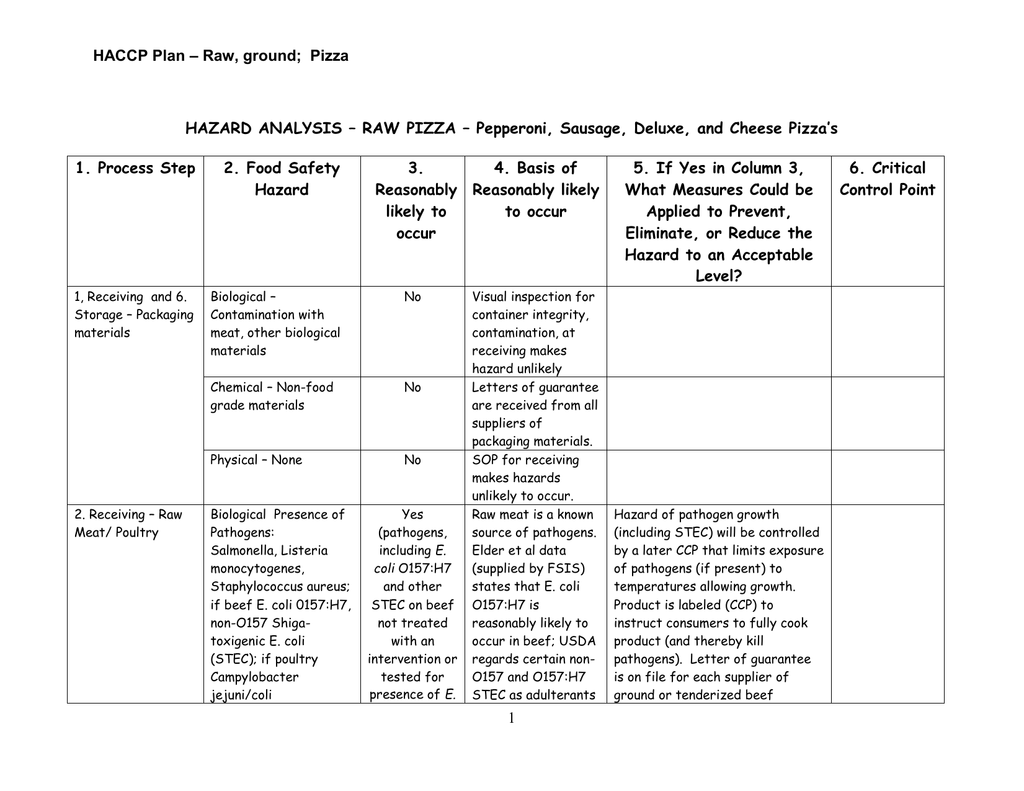

Therefore HACCP analysis of this product is important issues for public health. The purpose of the Penn State Extension Food Safety Plans for Small-Scale Cheesemakers is to assist small-scale and raw milk cheesemakers in conducting hazard analyses of their processes to ensure they are producing the safest product possible and to meet the requirements of the Food Safety Modernization Act FSMA. The Hazard Analysis is a two-step process.

Cheese standards Food Contamination prevention control Food. Weibull hazard analysis plot for cottage cheese stored at 4C. The shredded cheese shall comply with 21 CFR 133146 for grated cheeses.

Acta Scientiarum Polonorum Technologia Alimentaria 93 2010 335 RESULTS AND DISCUSSION Development of UF white cheese HACCP plan 1. This cheese is a kind of fresh and soft cheese which is sold before ripening and is a popular type of cheese in Iran. Line a represents the shape parameter line.

When the shape parameter varies between 2 and 5 the corresponding distribution is nearly bell-shaped. To set up a specific HACCP plan for this small-scale cheese plant. Implementation of the Hazard Analysis Critical Control Point HACCP system.

HAZARD ANALYSIS Raw material Cheese Hazard Hazard Category B Salmonella spp. In a recent study on Monte Veronese cheese an Italian PDO semi- hard cheese made with raw milk Staphylococcus aureusnumbers in cheese were higher than the104CFU g-1limit in 78 of samples 1. See 21 CFR 117130b1i.

Axis that is parallel to the data line. The traditional inspection and quality procedure in order to prevent the hazards in the cheese product. HACCP Hazard Analysis Critical Contro l Points is a system that identifies evaluates and controls.

A Hazard Analysis is the process of collecting and evaluating information on hazards present to determine which are significant for food safety and must be considered in the Food Safety Plan. In this study a methodological. Brazil two cheese plants 13 10 Barancelli 2011.

The hazard analysis critical control point system HACCP is a widely used tool in the food industry and recommended in the water safety plans WSP approach.

Hazard Analysis Of Cheese Processing Steps Download Table

Hazard Analysis Of Cheese Processing Steps Download Table

Critical Control Points In Haccp System Set Up In Cream Cheese Production Download Table

Hazard Analysis Of Cheese Processing Steps Download Table

Implementation Of The Hazard Analysis Critical Control Point Haccp System To A Dairy Industry Evaluation Of Benefits And Barriers Semantic Scholar

Safety In Mind Swiss Cheese And Bowties Flight Safety Australia

Pdf Development Of A Haccp Plan For Listeria Monocytogenes Hazard Associated With Raw Milk Cheese Artisanal Production Process Semantic Scholar

Swiss Cheese And Safety Michigan Tech Research Blog

A Swiss Cheese Model For Reducing Biases In User Research By Biswajeet Das Ux Collective

Determinants Of Implementation Of Hazard Analysis And Critical Control Point Project In Four Selected Gouda Cheese Processing Firms In Rwanda Semantic Scholar

Haccp Plan For Pasteurized Milk Download Table

Haccp Implementation On Cheddar Cheese

Pdf Hazard Analysis Of Cheese Provided For Consumers In Hawassa Ethiopia

Pdf Implementation Of Hazard Analysis Critical Control Point To Feta And Manouri Cheese Production Lines Semantic Scholar

Pdf Control Of Haccp System Efficiency In Cream Cheese Production Semantic Scholar

Comments

Post a Comment